Implementing a real-time data system in a quarry can revolutionize operations, leading to increased efficiency, reduced costs, and enhanced safety. This guide walks you through the critical steps to successfully set up and integrate a real-time data system tailored to the needs of your quarry.

1. Choosing the Right Technology

A. Identify Key Operational Goals

Before selecting any technology, define the specific problems or opportunities you want to address with real-time data. Common objectives include:

- Monitoring equipment performance to reduce downtime.

- Tracking fuel consumption for cost savings.

- Enhancing safety through predictive maintenance and environmental monitoring.

By clarifying your goals, you’ll be better equipped to select a system that meets your needs.

B. Evaluate Compatibility and Scalability

When choosing a real-time data system, ensure it integrates with your existing equipment and telematics. Consider systems that:

- Are compatible with IoT sensors and devices already in use on your site.

- Can scale with your operations if you expand to new sites or add more equipment.

- Offer cloud-based data storage and access, which facilitates remote monitoring across multiple sites.

C. Choose Between On-Premise vs. Cloud Solutions

- On-Premise: Data is stored locally, offering more control but requiring greater IT infrastructure.

- Cloud-Based: More flexible, lower upfront costs, and enables access to real-time data from anywhere. This is often the preferred choice for quarries looking for scalability and ease of use.

D. Compare Vendors

Select a vendor with proven experience in the quarrying industry. Look for:

- Positive customer reviews and case studies.

- Robust support and technical services.

- Systems that integrate easily with both heavy machinery and software systems like fleet management or ERP tools.

2. Sensor and Hardware Installation

A. Identify Key Machinery and Areas for Monitoring

Start by determining where real-time data will have the most significant impact:

- Heavy Machinery: Install sensors on key assets like excavators, loaders, conveyors, and crushers to monitor health metrics such as temperature, vibration, fuel consumption, and engine performance.

- Environmental Monitoring: Set up sensors in areas where safety is a concern—such as air quality monitors, dust particle sensors, or proximity sensors near high-risk zones.

- Fuel Tanks: Use sensors to track fuel usage and identify inefficiencies in consumption.

B. Install IoT Sensors

Work with a professional installation team to equip your machinery with IoT sensors. These sensors collect the data needed to make informed, real-time decisions. Make sure to:

- Use robust, weather-resistant hardware that can withstand tough quarry conditions.

- Place sensors in easily accessible locations for regular maintenance checks.

C. Connect Sensors to Data Network

Ensure that sensors are connected via a stable, high-bandwidth network (often wireless or cellular). This step is essential for transmitting the data from the sensors to the centralized data platform in real-time.

D. Perform Initial Tests

Once sensors are installed, conduct testing to ensure that data is being accurately transmitted from the hardware to your centralized system. Adjust any sensors or connections that show issues during testing.

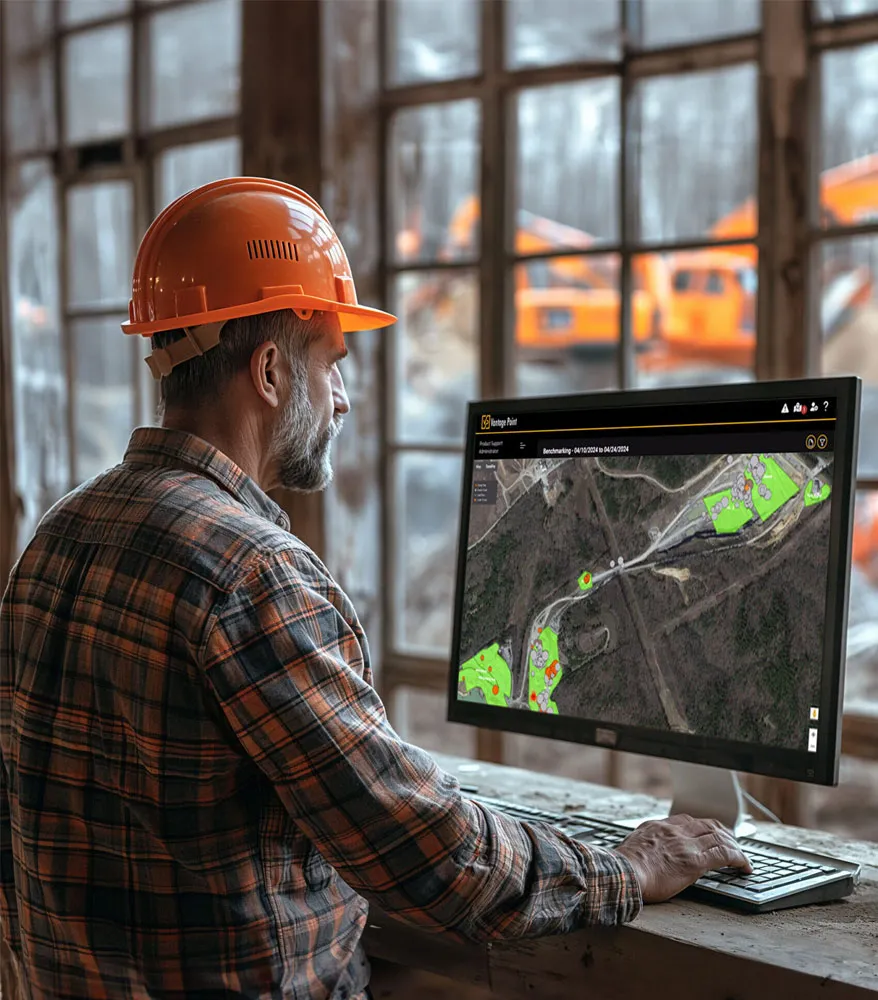

3. Data Dashboard Setup

A. Select a Dashboard Platform

The data dashboard is your operational nerve center. It gathers and displays real-time data from all connected sensors. When choosing or setting up a dashboard, prioritize platforms that:

- Offer customizable views to focus on the KPIs that matter most to your quarry.

- Provide real-time alerts for maintenance, safety issues, or performance inefficiencies.

- Support data visualization with easy-to-read graphs and charts.

B. Configure Alerts and Notifications

Set up automated alerts based on predefined thresholds. For example:

- Receive an alert if a machine’s temperature exceeds safe levels.

- Get notified if fuel consumption spikes unexpectedly or drops below a set point.

- Trigger safety warnings if proximity sensors detect unauthorized entry into hazardous areas.

C. Customize KPI Displays

Tailor the dashboard to display the most critical metrics:

- Machine Performance: Show real-time data on uptime, downtime, operational hours, and equipment health.

- Fuel Efficiency: Monitor fuel consumption and inefficiencies.

- Safety Compliance: Track safety incidents, environmental conditions, and compliance checklists.

D. Set Up Remote Access

For quarries operating across multiple sites or for management overseeing operations remotely, ensure the dashboard supports remote access. Cloud-based dashboards are ideal for accessing data on mobile devices, enabling real-time decision-making from any location.

4. Staff Training and Technical Support

A. Train Operators and Managers

To fully leverage the benefits of a real-time data system, staff must be proficient in using the new technology. Training should include:

- Basic System Use: Ensure operators and managers understand how to read dashboards, interpret data, and respond to alerts.

- Maintenance Procedures: Train teams to carry out regular maintenance on sensors and equipment to ensure long-term functionality.

- Data-Driven Decision-Making: Educate managers on how to turn data insights into actionable strategies that align with the quarry’s operational goals (e.g., adjusting machinery usage to save fuel or scheduling preventive maintenance based on sensor feedback).

B. Offer Ongoing Technical Support

Ensure that your staff has access to ongoing technical support, especially during the initial phases of system implementation. Choose a system provider that offers:

- 24/7 Technical Support: A dedicated team to troubleshoot sensor issues or platform malfunctions.

- Regular System Updates: Continuous software updates to ensure compatibility with the latest technologies and performance improvements.

- Field Service Technicians: On-the-ground support when hardware maintenance or sensor replacements are needed.

C. Create a Feedback Loop

Implement a process for gathering feedback from operators and foremen who use the system daily. This can highlight opportunities for further training, system adjustments, or dashboard customization. Continuous improvement through feedback ensures the system continues to meet evolving operational needs.